About Quality Management System for Medical Devices

ISO 13485 is an international standard that outlines the requirements for a Quality Management System in the medical device industry.

This standard is specific to medical devices and covers the entire life cycle of a device, from design and development to production, installation, and servicing. It is intended to ensure that medical devices are safe and effective for their intended use. Compliance with ISO 13485 is often required for regulatory approval of medical devices in many countries around the world. The standard is designed to be flexible and scalable, allowing it to be adapted to the needs of organizations of all sizes and types within the medical device industry

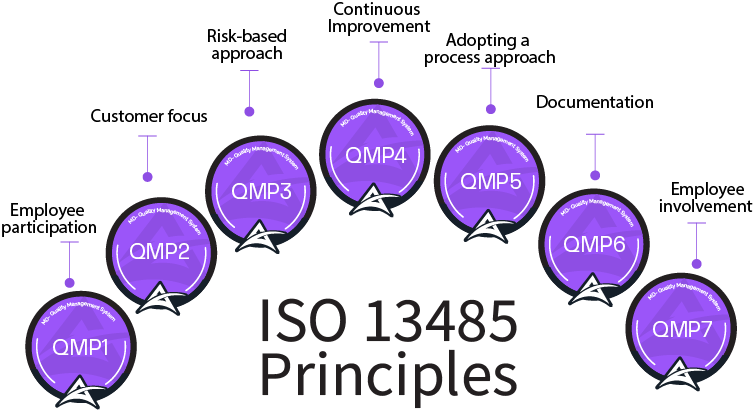

Quality Management System for Medical Devices Principles

Focus of Quality Management System for Medical Devices

Establish and maintain a specific quality management system for medical devices. Ensure compliance with regulatory requirements for medical devices. Implement risk management processes to identify and mitigate potential risks. Define and control processes for the design, development, production, and service of medical devices. Establish clear leadership responsibilities and commitment to quality. Efficiently allocate resources to support the quality management system. Conduct validation and verification activities to meet specified requirements. Implement procedures for monitoring and measuring processes, identifying areas for improvement. Implement measures to identify, segregate, and address nonconforming products. Establish processes for addressing nonconformities, implementing corrective and preventive actions. Maintain traceability of medical devices throughout production and service processes. Document and record information to demonstrate compliance with ISO 13485 requirements. Conduct regular internal audits to assess the effectiveness of the quality management system. Ensure effective control and monitoring of suppliers for materials and services used in medical device production

Benefits of Quality Management System for Medical Devices

Demonstrate compliance with regulatory and legal requirements

Ensure the establishment of QMS practices that consistently yield safe and effective medical devices

Manage risk effectively

Improve processes and efficiencies as necessary

Gain a competitive advantage

Frequently Asked Questions

ISO 13485 Medical devices — Quality management systems — Requirements for regulatory purposes is a voluntary standard, published by International Organization for Standardization (ISO) for the first time in 1996, and contains a comprehensive quality management system for the design and manufacture of medical devices.